Because the use of chemicals, especially hazardous ones, is such a precise process, the control valve must often perform to exacting standards. The valves are designed to handle brutal acidic, corrosive, abrasive, and other hazardous conditions.

The oil and gas industry is a subset of the pipelines category. Due to the high demand for oil and gas, deeper wells, longer pipelines, and lower production costs have become necessary. Along with the need for an inexpensive valve, the device must also be tougher, last longer, and perform better to meet the demands of the industry. Valve service environments and operating conditions are often extreme with high temperatures (greater than 1,500°F) and high pressure (greater than 25,000 psig) or cryogenic and very low pressure applications. Another feature important to valves used in the oil and gas industry is the capacity for remote control.

Control valves are used to provide modulating control in emergency cooling systems of power plants. The Main Steam Safety Valve is designed according to ASME requirements and in usage in all power plants.

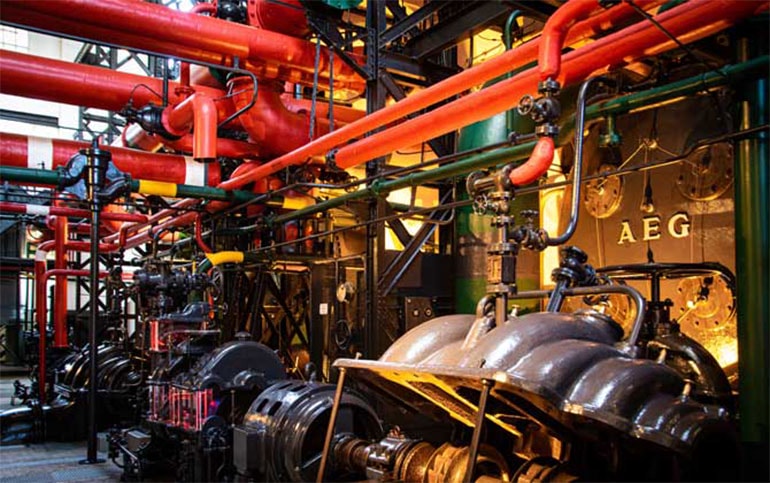

Hydraulic supply station is usable for hydraulically valves and it is providing hydraulic oil supply for control systems. It supports the hydraulic equipped system with continued oil pressure to ensure valve operations. For applications in coal fired power plants, combined cycle power plants, industrial power plants, other steam boiler applications and/or turbine bypass applications.

It is essential that water treatment facilities use the correct valves in their systems. Doing so ensures that piping systems operate consistently, effectively and safely, which prevents unnecessary maintenance.

The nature of sugar production and refining industry requires uninterrupted and continuous service of the plant for as much as 300 days in a year. This demanding process puts valves, actuators and controls through harsh and tough conditions. Continuous service and up-time are critical to the profitability of the plant and it is essential that those valves and actuators supplied into the sugar industry are able to successfully withstand the conditions.

Continuously working with corrosive and erosive fluids under high pressure and at high temperatures. Splashing of pulp and alkaline, vibrations created by refiners and pumps, pressure shocks, crystallisation and scaling, impurities such as sand and metal wires. It is under these conditions valves installed in the pulp and paper industry have to work and to work properly as a failure will cause tremendous costs.

Along the many miles of piping, Petroleum refineries require dependable isolation of critical equipment and control of process flow, coupled with reliable vent and drain valves. A valve’s performance ensures not only the integrity of the process and safety of plant personnel, but also the volume and rate at which the plant can produce products—thus generating revenue and enhancing profitability.

Valves play a critical role in the marine industry. As ships become larger and are used more frequently, they require the ability to generate power, treat and manage wastewater and control HVAC, as well as perform their required tasks. The size and application of the ship will determine the different types and number of valves on board. Valves are used to regulate the loading and storage of a ship’s power supply, provide water for fire-fighting capabilities, handle and processes wastewater and store any liquid cargo, among many other applications. Any valve that processes sea water must be durable, and all marine valves must be reliable due to lack of resources once out at sea.

Marine valves perform many different duties both above and below the decks of the ships. All vessels need some form of energy to power their engines, and valves regulate the loading and storage of whatever is used. A diesel tugboat might have only one fuel valve, while a large cargo ship may have a complicated system of pumps and manifolds with multiple valves directing the fuel to various tanks on the ship. Oftentimes, these tanks are located at strategic points to aid in the ballasting of the vessel.

The key components of a fire fighting system begin with high-quality valves like Isolation Ball Valves, Gate valves, Check valves Alarm check valves, Zone control valves, Pre-action valves, Pressure reducing valves, etc. Untold damages to a property can be done by a sudden fire event, but sometimes efforts to put out the fire can be very catastrophic. The base of a fire protection system is made by high-quality, high-performance fire fighting valves which deliver water safely and efficiently when you require it the most.

Lowering pressure loss by venting air from cooling water pipelines and pumping stations. Controlling of process gas and process liquid flows in discharge pipelines. Blocking of process gas and process liquid flows in discharge pipelines. Preventing backflow of process gas and process liquid flows in discharge pipelines. The blast furnace also requires a variety of water and steam lines. These lines and their accompanying valves are usually built to standard designs.

The processes in this industry require valves for cement that are highly abrasion and wear resistant, because of the nature of materials used in the manufacturing of cement.

Valves for aerospace applications are typically very small. The most common types are solenoid valves and small hydraulic valves used to manipulate the control surfaces such as the ailerons, flaps and rudder. Guided missiles and rockets use the same types of small and micro-sized valves.

The launching pads for orbital and space exploration rockets are very complex and contain a variety of pipe lines. There are lines for liquid fuel, which usually contain cryogenic valves. Other utility lines contain a variety of fluids at differing pressures and temperatures.