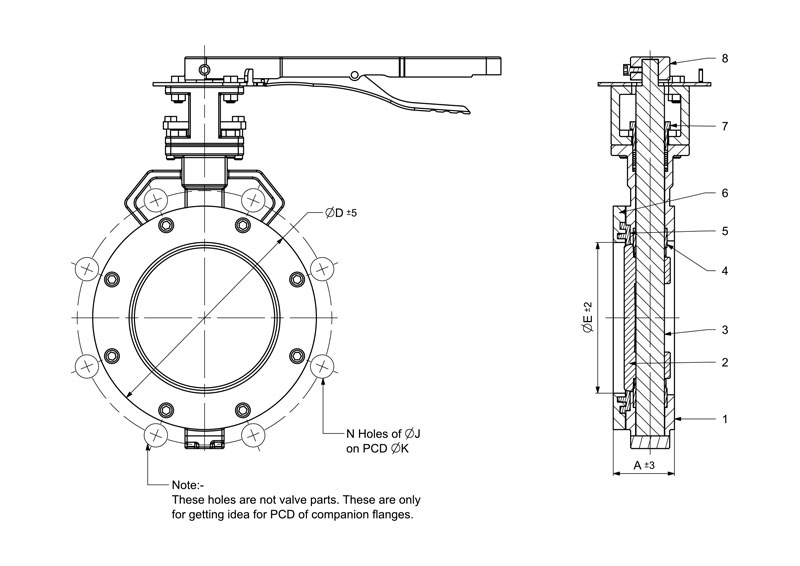

X2HPDOBFV are available in Wafer and Lug type designs conforming to API 609 standard. The Disc construction is Double Offset providing excellent controllability, bubble tight shut off, greater seat life and smooth operation. Valves are specially designed for applications in Chemical, Petroleum, Hydro Carbons Processing, Pulp & Paper and HVAC industries. Well supported shaft with heavy duty bearings ensure perfect alignment of seat and disc for smooth and trouble free operations. Valves have been rigorously tested to ensure industry performance requirements.

MOC:

WCB/CF8/CF8M - (CF3/CF3M And high nickel Alloys on Request)

Valve Design:

Eccentric (Double Offset) Design

Size:

40mm to 150mm (1 1/2" TO 6")

End Connection:

Wafer End

Pressure Class:

PN10/PN16

Operation:

Manual

Design & manufacturing Standard:

BS EN 593 / ISO 5211

Testing & Inspection:

API 598

Face to Face:

BS EN 558

| No. | Description | Material |

|---|---|---|

| 1 | Body | WCB/CF8/CF8M- (CF3-CF3M On Request) |

| 2 | Disc | WCB/CF8/CF8M- (CF3-CF3M On Request) |

| 3 | Stem | SS304/SS316/SS410 |

| 4 | Stem Bush | SS304/SS316/SS410 |

| 5 | Seat Ring | PTFE/GFT |

| 6 | Retainer | MS/CF8/CF8M |

| 7 | Gland | CF8/CF8M |

| 8 | Handle | MS with Powder coating |

| Test Type | Unit-Bar | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 15 | 220 |

| Hydro Seat | 11 | 160 |

| Air/Pneumatic | 7 | 80 |

| Test Type | Unit-Bar | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 24 | 340 |

| Hydro Seat | 16 | 230 |

| Air/Pneumatic | 7 | 80 |