Socket weld end ball valves are robust industrial valves designed for high-pressure applications. They feature a welded connection for enhanced strength and durability. These valves provide reliable control over fluid flow with a quarter-turn operation mechanism, making them efficient and easy to use. Ideal for use in pipelines, refineries, and chemical plants, socket weld end ball valves ensure secure sealing and minimal leakage, offering safety and efficiency in demanding environments.

MOC:

WCB/CF8/CF8M/CF3/CF3M And high nickel Alloys,Etc.

Valve Design:

Three Piece Construction

Size:

15mm to 50mm (1/2" TO 2")

End Connection:

Socket Weld End (ASME B16.11)

Pressure Class:

150#

Operation:

Manual

Design & manufacturing Standard:

ISO 17292 / BS 5351

Testing & Inspection:

API 598 / BS 6755

Valve Bore:

Full Bore

Face to Face:

Manufacturing Standard.

Temp. Range:

-20 TO 180°C

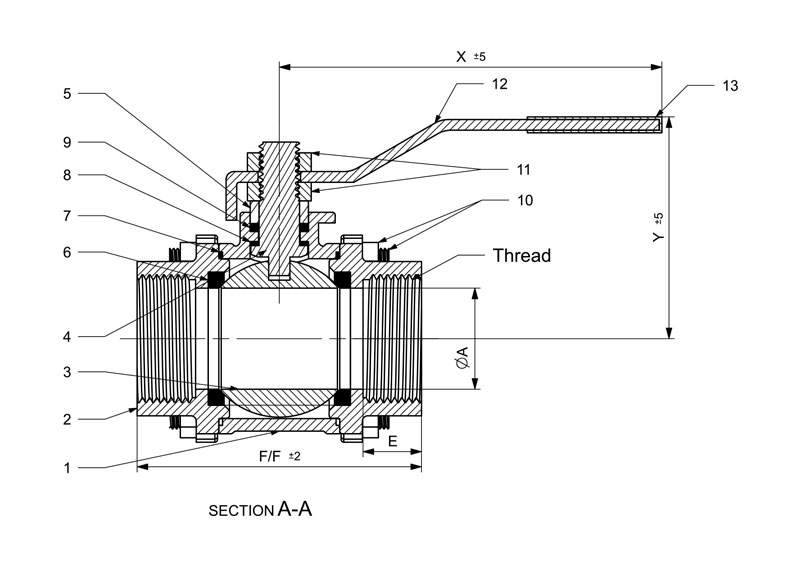

| No. | Description | Material |

|---|---|---|

| 1 | Body | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M/td> |

| 2 | Tail Piece | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| 3 | Ball (Hollow/ Solid) | ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| 4 | Seat Ring | PTFE/GFT/CFT/TFM |

| 5 | Body Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| 6 | Stem Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| 7 | Gland Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| 8 | Gland | SS304/SS316/SS304L/SS316L/SS410 |

| 9 | Lock Nut | SS202/SS304/SS316/MS |

| 10 | Stem | SS304/SS316/SS304L/SS316L/SS410 |

| 11 | Handle | SS202/SS304/SS316/CS |

| 12 | Sleeve | PVC |

| 13 | Nut | SS202/SS304/SS316/2H/MS |

| 14 | Stud | SS202/SS304/SS316/B7/MS |

| Test Type | Unit-Kg / Cm2 | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 32 | 430 |

| Hydro Seat | 22 | 315 |

| Air/Pneumatic | 7 | 80 |