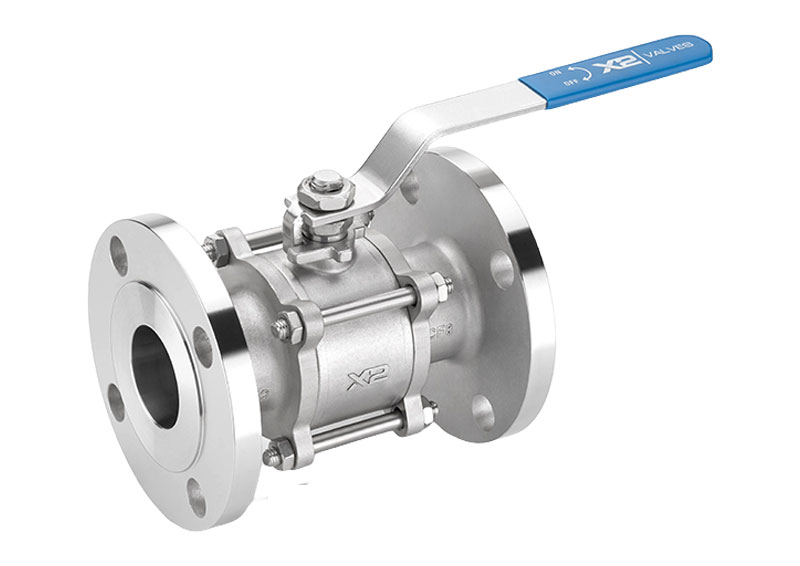

Probably the most popular type of ball valve is the Three-piece design. The 3-piece ball valve is ideal for almost any application where a straightforward on/off action is required. It can swiftly and easily open or shut off flow for the majority of liquids, oils, and gases. By varying the degree of partial opening or closure of the valve, the flow rate can also be managed. It is also known as a two-way ball valve because it permits bidirectional flow from the inlet to the outlet. This valves are used for high working pressure in Gas Application.

MOC:

WCB/CF8/CF8M/CF3/CF3M And high nickel Alloys,Etc.

Valve Design:

Three Piece Construction

Size:

15mm to 150mm (1/2" TO 6")

End Connection:

Flanged End (ASME B16.5)

Pressure Class:

300#

Operation:

Manual

Design & manufacturing Standard:

ISO 17292 / BS 5351 / API 6D /ISO 5211

Testing & Inspection:

API 598 / BS 6755

Fire Safe:

Fire Safe Design

Valve Bore:

Full Bore

Face to Face:

ASME B16.10

Temp. Range:

-20 TO 180°C

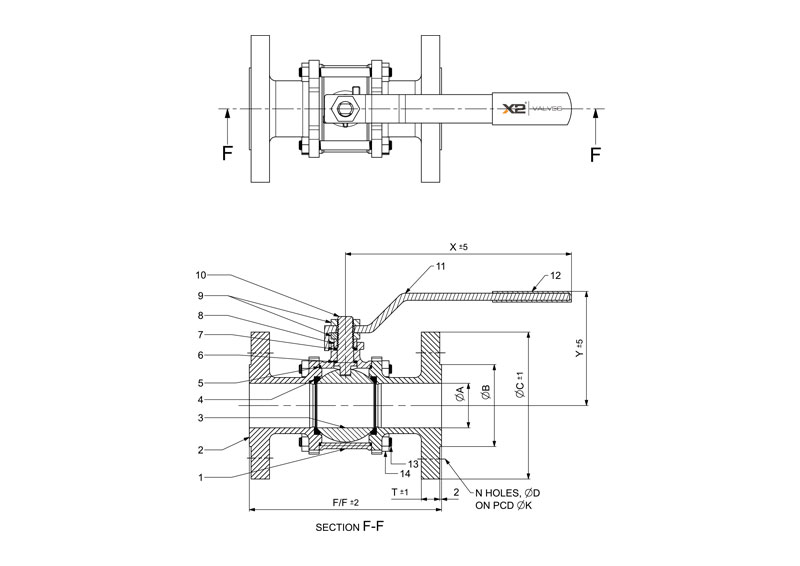

| No. | Description | Material |

|---|---|---|

| 1 | Body | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| 2 | Tail Piece | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| 3 | Ball (Hollow/ Solid) | ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| 4 | Seat Ring | PTFE/GFT/CFT/TFM |

| 5 | Body Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| 6 | Stem Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| 7 | Gland Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| 8 | Gland | SS304/SS316/SS304L/SS316L/SS410 |

| 9 | Lock Nut | SS202/SS304/SS316/MS |

| 10 | Stem | SS304/SS316/SS304L/SS316L/SS410 |

| 11 | Handle | SS202/SS304/SS316/CS |

| 12 | Sleeve | PVC |

| 13 | Stud | SS202/SS304/SS316/B7/MS |

| 14 | Nut | SS202/SS304/SS316/2H/MS |

| Test Type | Unit-Kg / Cm2 | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 80 | 1140 |

| Hydro Seat | 56 | 815 |

| Air/Pneumatic | 7 | 80 |