X2CDBFV model Butterfly valve incorporates the optimum design features to provide long trouble free service in the field. This general purpose soft seated Butterfly valve has a fully rubber lined single piece body with a centric disc construction and is available in wafer type body paten. The body liner which also functions as the soft seat, comes in either a replaceable version or an integrally moulded (bonded) version and offers - 100 % bi-directional sealing against full vacuum to rated pressures of PN10 or PN16. The wafer style body has universal design to fit between pipe flanges of almost all popular flange standards.

MOC:

CI/WCB/CF8/CF8M - (CF3/CF3M And high nickel Alloys on Request)

Valve Design:

Concentric Design

Size:

40mm to 200mm (1 1/2" TO 8")

End Connection:

Wafer End

Pressure Class:

PN10/PN16

Operation:

Manual

Design & manufacturing Standard:

BS EN 593 / ISO 5211

Testing & Inspection:

API 598

Face to Face:

BS EN 558

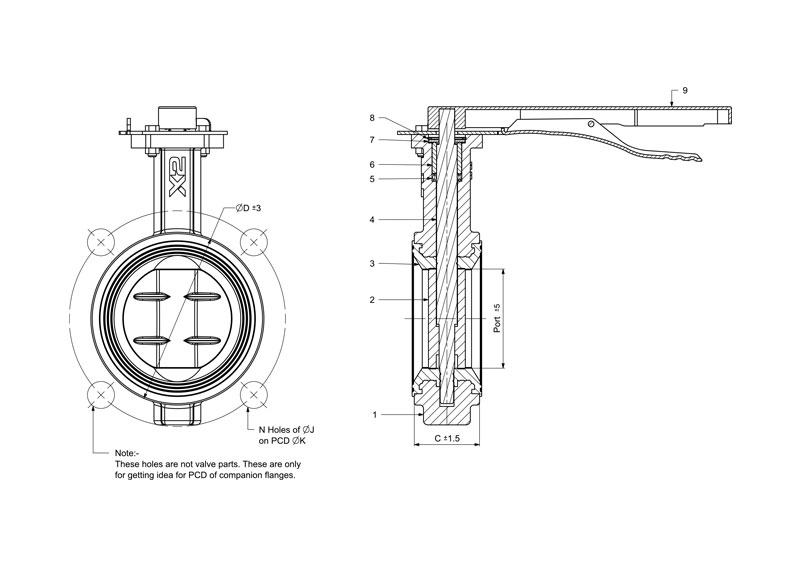

| No. | Description | Material |

|---|---|---|

| 1 | Body | Cast Iron/Ductile Iron/S.G.Iron/WCB/CF8/CF8M- (CF3-CF3M On Request) |

| 2 | Disc | S.G.Iron/WCB/CF8/CF8M- (CF3-CF3M On Request) |

| 3 | Seat | EPDM/Nitrile/Neoprene/Viton/Silicon |

| 4 | Stem | SS304/SS316/SS410 |

| 5 | O-Ring | Rubber |

| 6 | Bush | PTFE |

| 7 | Washer | SS304 |

| 8 | Circlip | Spring Steel |

| 9 | Handle | MS with Powder coating |

| Test Type | Unit-Bar | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 15 | 220 |

| Hydro Seat | 11 | 160 |

| Air/Pneumatic | 7 | 80 |

| Test Type | Unit-Bar | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 24 | 340 |

| Hydro Seat | 16 | 230 |

| Air/Pneumatic | 7 | 80 |