A forged steel gate valve is a type of valve used to control the flow of liquids or gases in a pipeline. These valves are known for their durability, strength, and reliability, making them suitable for high-pressure and high-temperature applications. The term "forged steel" refers to the manufacturing process where steel is shaped under high pressure to increase its structural integrity.

MOC:

ASTM A105/ ASTM A182 Gr. F304/F316

Size:

15mm to 50mm (1/2" TO 2")

End Connection:

Flanged End (ASME B16.5) / Secrewed End / Socket Weld End / Butt Weld End

Pressure Class:

150#/300#/600#/800#/1500#/2500#

Design & manufacturing Standard:

API 602 / ISO 15761 / ASME B16.34

Testing & Inspection:

API 598

Valve Bore:

Reduce Bore / Full Bore

Face to Face:

Manufacturing Std.

Temp. Range:

-29°C to 425°C.

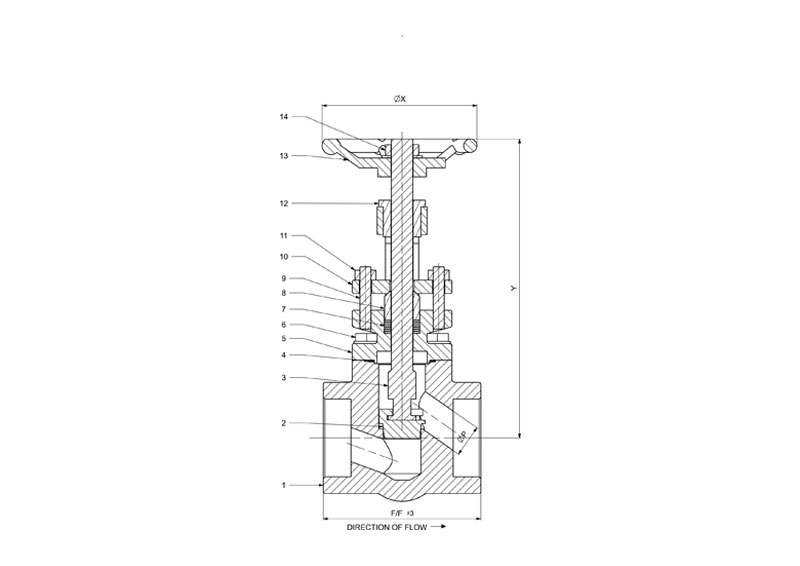

| No. | Description | Material |

|---|---|---|

| 1 | Body | ASTM A105 |

| 2 | Plug | ASTM A217 Gr CA15 |

| 3 | Stem | ASTM A182 Gr F6a |

| 4 | Gasket | SS 316 Spiral Wounded Graphite |

| 5 | Bonnet | ASTM A105 |

| 6 | Hex Bolt | ASTM A193 Gr B7 |

| 7 | Gland Packing | Flexible Graphite Rings |

| 8 | Gland Bush | ASTM A276 Type SS410 |

| 9 | Stud | ASTM A193 Gr B7 |

| 10 | Gland Flange | AASTM A105 |

| 11 | Stud Nut | ASTM A194 Gr 2H |

| 12 | Yoke Sleeve | BS970 : 1955 EN1A |

| 13 | Hand Wheel | ASTM A105 |

| 14 | Stem Nut | ASTM A194 Gr 2H |

| Test Type | Unit- Kg/Cm² |

|---|---|

| Hydro. Shell | 208 |

| Hydro. Seat | 153 |

| Air/Pneumatic | 7 |